Industrial Polymer

Mold Cleaning in Semiconductor

Mold cleaning process was a mandatory process for Semiconductor to clean away the epoxy deposits formed during the molding process for Integrated Circuit, Diodes, transistor etc. Cleaning method includes the Melamine Based Cleaner and Rubber Base mold cleaner.

Cleaning methology

End users shall apply different combination of cleaning methology depend on cost factors, internal requirement, customers requirement and well as productivity aspect. Rubber Sheet cleaner is a fast cure material compare to Melamine base cleaner. It does not need any lead frame and preheating for performing the cleaning process. With the elimination of preheating and shorter cure time, customer can gain productivity improvement with Rubber Base Cleaner.

RUBCLEAN

Specially formulated compound for the cleaning of thermosetting transfer mold. It has its excellent elastic properties which easing the removal of the compound from the mold without leaving any unwanted debris and assist in the house keeping of the molding station. Besides , it was also formulated with high flow characteristic to achieve cleaning efficiency. It emits limited odor during the cleaning process.

Rubcleann Application Procedures

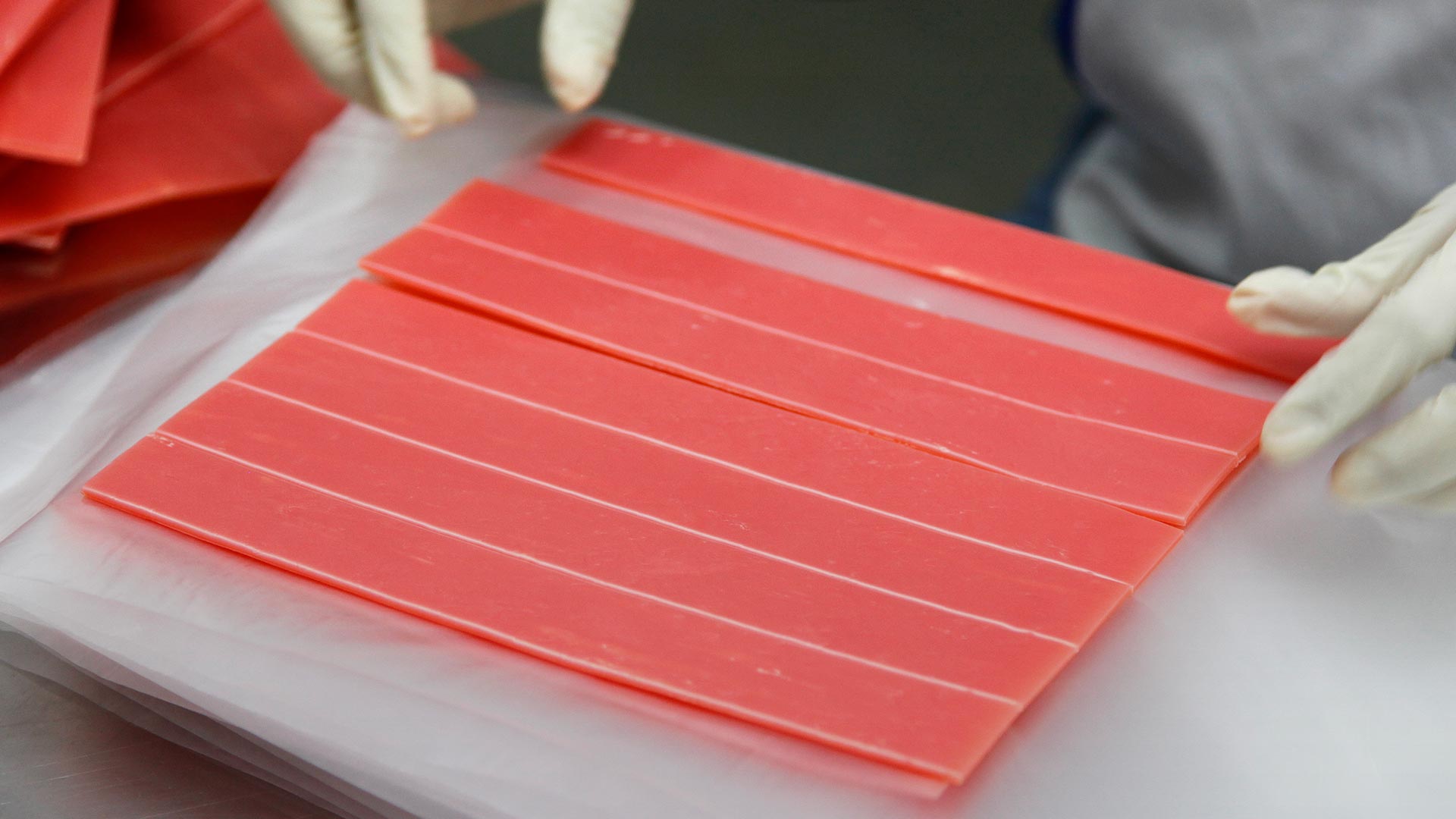

- Locate Rubclean on mold chase with required number of strips.

1 to 2 Rubclean strips per mold chase depending on mold cavities dimensions. - Clamp the mold to compress Rubclean until complete filling in the cavities is achieved.

- Over clamping the compound may cause releasing difficulty from mold.

- Suggested rubber cure time is depending on mold temperature. For normal molding temperature of 175 +/-5 °C, the suggested compound cure time is 180 to 240 seconds.

- Remove the cured rubber compound from mold and continue with Rubclean until the desired mold cleanliness is achieved.

- Number of cleaning shots suggested is 4 to 5 shots. However, this will be varied by mold conditions and mold compounds used.

- Over curing Rubclean (more than 10 minutes for 180 °C) might create sticking problem to the mold.

ELASTOWET

Specially formulated compound for wetting and conditioning of thermosetting transfer mold after mold cleaning. Elastowet has good compatibility with Rubclean. It also has excellent elastic properties to ease the removal of cured rubber after molding.It also has high flow characteristic to ensure rubber wax flow into all cavities to achieve waxing homogenous during the conditioning process.

Elastowet Application Procedures

- Locate Elastowet on mold for the required number of strips. 1 to 2 Elastowet strips per mold chase depending on the frame and mold cavities dimensions.

- Clamp the mold to compress Elastowet to fully fill up all the mold cavities. Over clamping the compound may cause releasing difficulty from mold.

- Suggested compound cure time is depending on mold temparature. For normal molding temperature of 175 +/- 5 °C, the compound cure time required can be from 180 to 240 seconds.

- Number of conditioning shots suggested is 1 to 2 shots after mold cleaning.

- Over curing Elastowet (more than 10 mins for 180 °C) might create sticking problem to the mold.

Rubber Application

Recommend Application Conditions

ADVERVANTAGE OF

Rubclean and Elastowet

- Air vents, cavities and mold surfaces cleaning & conditioning in single step.

- Cost saving in total cleaning materials.

- Shorter cleaning time & productivity gain.

- Cater for green compound requirements.

- Environmental friendly, using non hazardous ingredients and Halogen Free.

- No preheat, no lead frame, no thawing time is needed.

- Suitable for semiconductor, optoelectronics, rubber, plastic and metal molding industries.

Appearance: Rubber strips cut to customers’ required dimension

Dimension Option: (100-300) X (10-80) X (3-10) mm

Additional information Cape Rubclean and Elastowet were ROHS and REACH compliance.

For more details, please download the Product’s Technical Bulletin and Safety Data Sheet.

We tailored made polymer’s dimension

to meet semiconductor requirements.

Let’s discuss how our specialist can help.